Richard Seale recently posted a very informative and interesting series of articles surrounding Continuous and Batch Distillation on his personal page, with his agreement I have collated them into one single reference article below.

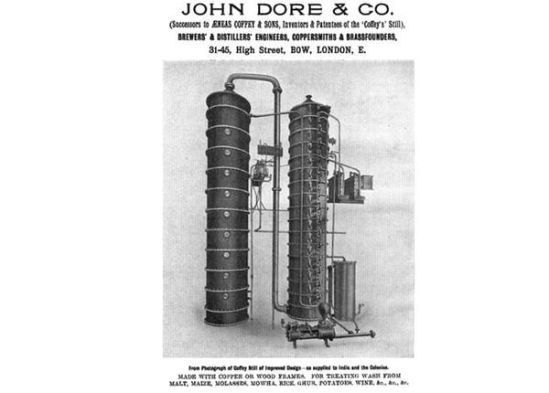

Aeneas Coffey, John Dore and Foursquare

Part One – The Continuous Still

Aeneas Coffey was not the first to invent the continuous still, nor was it the first continuous still to be used in Scotch Whisky however between 1834 and the 1876, seventeen newly installed Coffey stills would be making whisky in Scotland. It proved the foundation for the development of blended scotch whisky (developed around 1860), arguably the most successful spirit category of them all. How did it all happen? What follows is really only a brief overview of a history that is both very complex and very profound.

The late 18th century through the mid 19th century saw remarkable developments in spirit distillation. A drive to increase proof, efficiency and throughput underpinned these developments. We are focusing on the British, Irish and European developments as this directly impacted the West Indies but the American story is also very complex and worth your time.

Early stills by Adam (1801), Pistorius (1817) and Corty (1818) and several others too numerous to detail were essentially modifications of the simple batch (pot) still to add fractionation to simple distillation. In London at the Belmont Distillery in Vauxhall Jean-Jaques Saint Marc patented a batch (pot) still with a rectifying head in 1824. While used by Saint Marc for potato spirit, this concept would be a forerunner of the carter-head and the ‘Lomond’ still at Loch Lomond distillery. A notable step (see the post script) but still in the realm of discontinuous (ie batch) distillation.

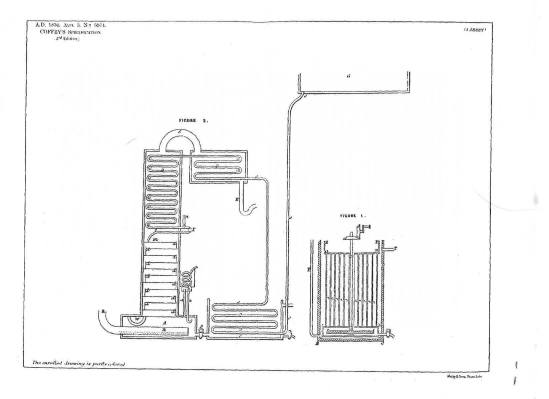

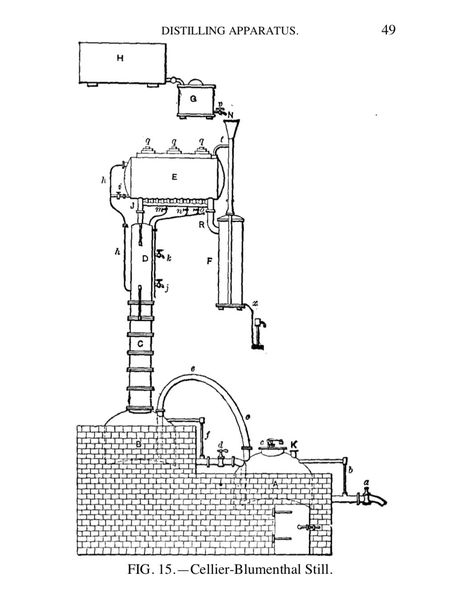

The first genuine continuous still was patented by Jean-Baptiste Cellier-Blumenthal in 1813. In 1828 Robert Stein, a member of the Stein-Haig distilling family would also patent a continuous still and this would be the first licensed continuous still used in Scotland at Cameronbridge in 1830. Coffey would first patent his continuous still in 1830 and it bore remarkable similarity to the Cellier-Blumenthal still.

Aeneas Coffey had been an Irish Inspector of Excise until his retirement in 1824. During his work as an excise officer he invented the Spirit Safe an early insight to his genius. Purportedly of French birth he may have had contact with the work of Cellier-Blumenthal. It was also thought he was familiar with another early continuous still of Cork distiller Anthony Perrier patented in 1822 as well as the continuous still of Robert Stein. Coffey’s Father, Andrew Coffey was the engineer in charge of the waterworks for the Dublin Corporation and reputed to be quite ingenious. He may have also had an influence on Coffey’s engineering skills. Coffey’s first still was at Dock Distillery in Dublin and licensed in 1832. This distillery was not successful and the business was soon changed to one of still manufacture. The first Coffey still in Scotland was at Grange in 1834.

Coffey proved not to be successful in Ireland. Kerr (1946) humorously reflected:

“between good advertising and the effeminate palates of the English, which were not robust enough to appreciate really good whisky like the Irish, this type of whisky [blended] captured the English market and still holds it to an undeserved extent”.

The reasons were likely more nuanced. The early Coffey stills used iron pipes which gave the whisky an unpleasant flavour no doubt contributing to the early failure. Ireland did not license small distillers and legal Irish whisky was dominated by large stills. We suspect this would have played a role in making Coffey’s continuous still less attractive by comparison. Big pot stills would have good throughput if not the fuel efficiency of the continuous still. Ironically, it was Coffey in his role as Excise Office who suppressed the small illicit distillers. In 1810, he was left for dead having been attacked with a bayonet during the ‘poitin wars’. A reward for the capture of his attackers was unsuccessful, excise officers then as now were less than popular.

In 1835, the firm Aeneas Coffey and Sons was established in Bromley in the UK. His failure in Ireland contrasted by early success in Scotland (Inverkeithing and Bonnington had soon followed Grange) and potential sales of his still to rectifiers and gin distillers probably prompted the move. In 1840, Aeneas Coffey Jr established the first patent distillery in London at Lewisham which ended in rather unfortunate circumstances. The Secretary arranged for a large release of spirits from bond and presented the cheque for excise duty at a Directors meeting which did not contain the payee’s name. The secretary filled in his own name, cashed the cheque and was never seen again. The distillery went bankrupt and the Coffeys once again continued on as still makers.

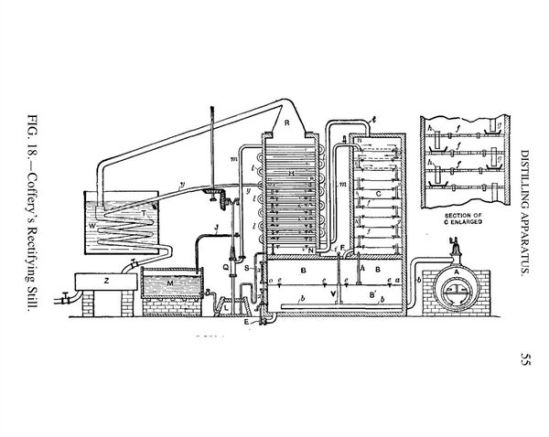

The success of the Coffey still was really due to the evolution of the original design which had been little more than an improved Cellier-Blumenthal still. By 1840, the Coffey still would have copper piping, copper plates (trays) perforated with bubble caps and the still was split into two columns – analyzer (or stripping) column and the rectifying column. This separation of stripping and rectifying would be the foundation of nearly every spirit still in operation today. The use of perforated copper plates (trays) would be a marked improvement on the Stein continuous still which did not have contacting plates and the wash needed to be misted to ensure good liquid / vapour mixing. Even the Haig family would install a Coffey still.

The Cellier-Blumenthal still would also be improved by French Engineer and Dutch Sugar Trader Armand Savalle and by French Pharmacist Louis-Charles Derosne. Savalle and Cellier-Blumenthal were collaborators. Cellier-Blumenthal would sell his patent to Derosne who improved it and filed his own patent while Savalle continued to work independently. Savalle stills can be found today in Demerara and the French Islands of Martinique and Guadeloupe.

While some un-malted grains had been used by highland single malt distillers the advent of the continuous still precipitated the split where highland batch stills were solely single malt with the cheaper un-malted grains going to the lowland continuous Coffey stills. This more economic and more available ‘grain whisky’ in the hands of entrepreneurs like John Dewar, James Chivas and William Teacher was the foundation of the enormous success that Scotch Whisky is today. Some luck played a role as well. In 1863, there was the phylloxera in France which had affected most of Europe by 1879. Blended Scotch filled the void for the well to do English created by shortages of claret and brandy.

The influence of raw materiel on the acceptance and adoption of the continuous still should not be underestimated. We see the same in rum. Demerara was the first to develop vacuum pan sugar – the famed Demerara sugar – but the corollary of that is vacuum pan molasses lower in value to muscovado molasses and Demerara was the first of the anglophone producers to adopt the continuous still. In Martinique, early restructuring of the sugar industry into central factories (and thereby pan sugar) in the mid 19th century is the pre-cursor to the city based (Saint Pierre) production of Rhum Industrial with pan molasses.

In Barbados the rum industry collapses after 1870, due to taxation and economic malaise. By the 1890s, the only estates still making rum are using lower value pan molasses as the famous ‘Barbados Molasses’ (made either as the prime product of the estate or secondary to muscovado sugar) is too valuable to be converted into Barbados rum (which is only sold locally at this time). Barbados would see its first continuous still using pan molasses in 1893 to fill the void as muscovado estates went out of rum production. By the 1920s centralisation of sugar factories (producing pan molasses) would be well underway and two more continuous stills would follow – one at Mount Gay and another in Bridgetown.

For Jamaica by contrast, rum was the primary product for many estates as it was more valuable than Jamaica Sugar. Rum in Jamaica was made from cane juice (Appleton) or ‘first boil’ molasses. Jamaica would not adopt the continuous still until the 1960s.

Notwithstanding the success of still sales to Scotland, the business of still making slowed by the late 1860s and in 1872, Philip Coffey, son of Aeneas would transfer the business to his long time foreman John Dore. Aeneas’s grandson, Aeneas H Coffey would act as consultant to John Dore for many years. By 1887, business would revive and Barnard’s – ‘The Whisky Distilleries of the United Kingdom’ – published that year reported Coffey Stills in all major Scotch Whisky distilleries.

John Dore & Co Ltd would continue as successors to Aeneas Coffey, still operating from Bromley and supply Coffey Stills to the West Indies including to Jamaica, Barbados, Guyana, St Vincent, St Lucia and Grenada. Coffey stills and their derivative designs would be also be sold by Scottish still makers such as Blairs and McMillans including to rum distillers in the West Indies. Following the general demise of British manufacturing, Blairs would cease operation in 1977 and John Dore would cease operating in the early 1990s although the trade mark was sold and has been used subsequently on stills built by other copper works. McMillans continues operations till this day although now it exclusively builds pot stills.

Post Script:

The addition of rectification in 1824 to a batch (pot) still before the development of the continuous (column) is notable. In fact as early as 1813, Florentine Baglioni added a column section to a batch still for grappa. Unfortunately, it did not work well with the ‘vinnacia’.

Today terms such as ‘hybrid still’ are a source of confusion. There is no such thing as a hybrid still. The dichotomy is not pot still v column still but batch still v continuous still. All still designs fall into one of the latter two categories. The addition of fractionation or enhanced rectification to a batch still is still a batch still. The simple batch still relies solely on the lyne arm for rectification. Enhancing this effect does not change the fundamental nature of the still.

A batch still will produce a changing output over time (colloquially the heads, then hearts, then tails) from a single charge (batch) that itself changes as it is distilled. A continuous still produces an unchanged output that varies by position (not by time) on an unchanging charge that is fed continuously. Heads, hearts, tails are drawn off simultaneously from different positions. This is the fundamental distinction between the two processes which also explains why the two can never make the identical spirit.

Early column shaped stills (e.g. the columnar Pistorius still) should not be confused with a column or continuous still, it was a batch still and the Savalle or Cellier Blumental stills are not fitted with “a pot still” just because they had a pot shaped base/kettle – there were in fact continuous (or column) stills.

Part Two – The Batch Still

The myriad of still patents developed between the late 18th and mid 19th century is extraordinary and the few mentioned in part one does not do it remotely justice. This work, applied to simple batch distillation led to the development of the continuous still and the distillation world never looked back.

Curiously, the extensive developments on batch distillation had little impact on the batch (pot) stills of Scotland, Ireland and Cognac and they continue to employ simple batch distillation, either double or triple to make whisky and cognac today. To see advanced batch distillation in the 19th and 20th century, one must travel to the West Indies and observe rum distillation.

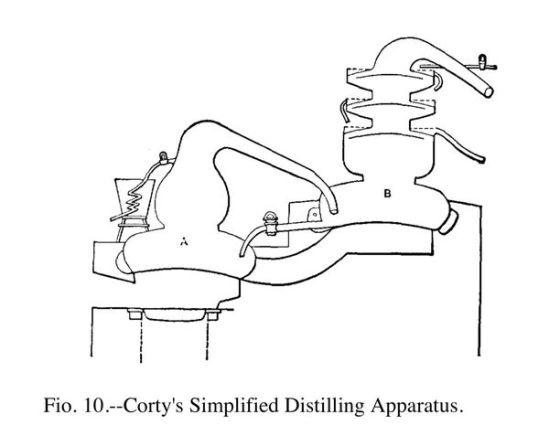

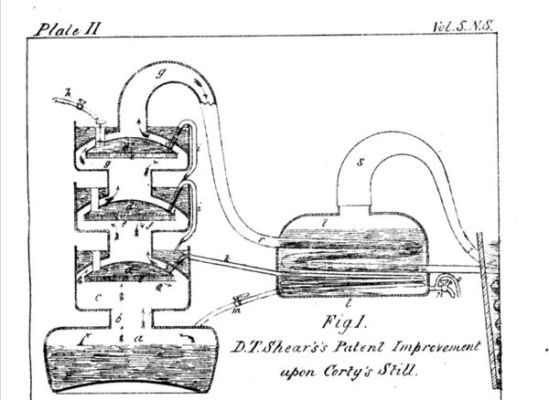

It is often claimed that the double retort still used in West Indies is an “Adam’s still”. No explanation is ever offered as to why the English colonies would have purchased a French still (of which only three were made) at the height of the Napoleonic wars (let alone been able to import it). As mentioned in part one, Edouard Adam (1801) made an improvement to the simple still. He did so by adding fractionation to the batch still via a series of egg shaped vessels. Adam’s work was based on the work of Professor Laurent Solimani and the two would go on to jointly patent further improvements. There is no denying the similarly in principle to a pot still with multiple retorts but how the West Indies came to use the double retort is rather more nuanced and much more likely from a parallel bit of work of Joseph Corty.

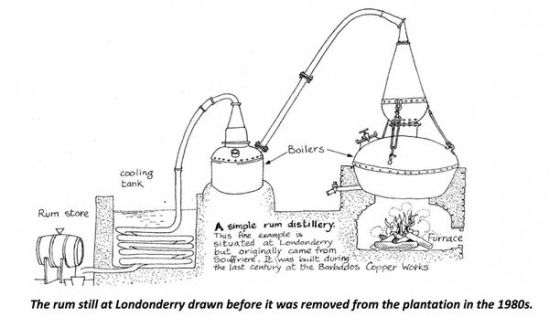

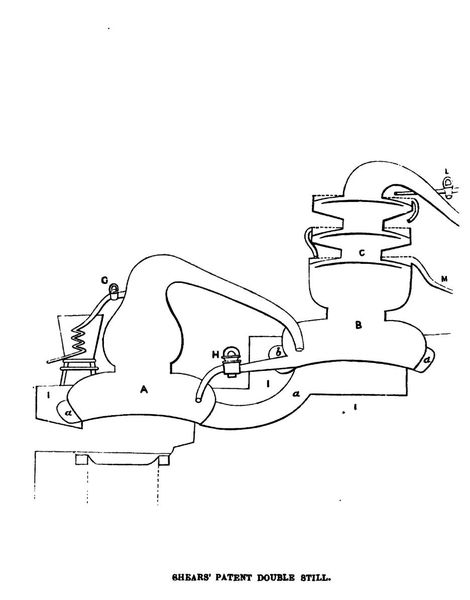

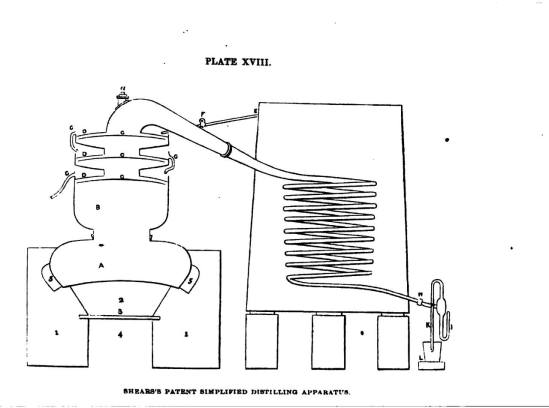

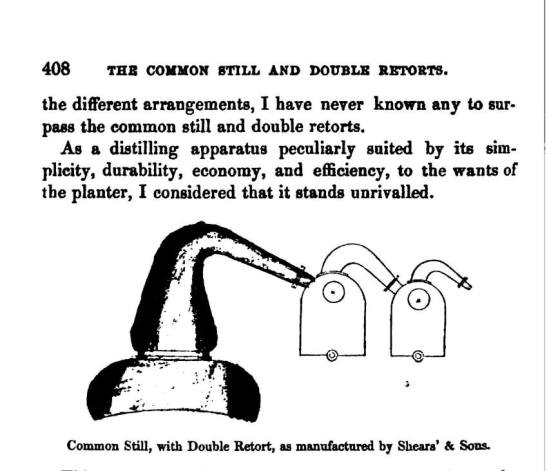

In 1818, Joseph Corty developed a double “compound” still with the second still containing external cooling (similar to that of Pistorius). DT Shears & Sons of Bristol would acquire this design and these double stills proved to be of “such repute” that Shears would supply “numbers of them for the colonies, but particularly Demerara” – Wray (1848). Double stills of varying designs could also found in the West Indies, some notable examples include one at the Londonderry Estate in Dominica (built at the copper works in Barbados) and of course the one at Port Mourant still in operation today. These double stills are the forerunner of the pot/double retort in common use today in Barbados, Jamaica, Guyana, St Lucia, Grenada among others. Early retort stills carried external cooling heads, no doubt the influence of the original Corty Still.

Leonard Wray (family to the perhaps better known J Wray) in his seminal work – The Practical Sugar Planter (1848) – wrote:

“But of all the arrangements, I have never known any to surpass the common still and double retorts”

This was no idle boast, Wray had extensive experience including of the Stills of Cellier-Blumenthal, Laugier (another type of double still) and Coffey.

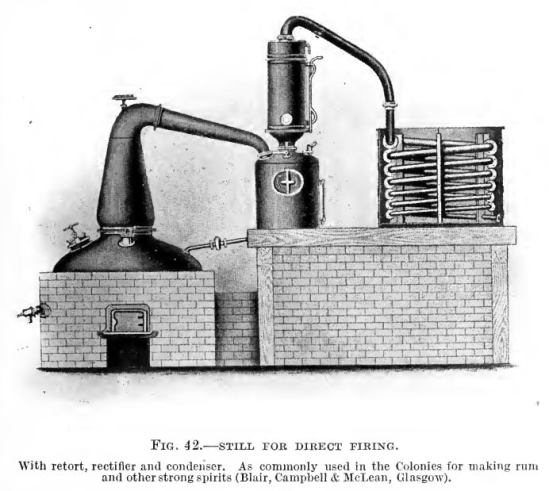

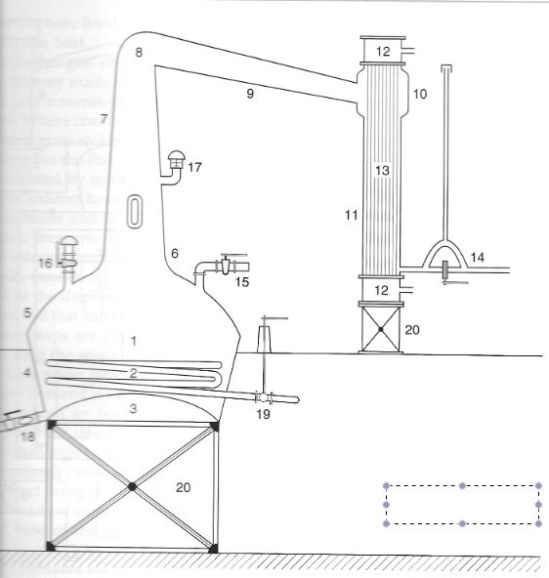

At this time double stills, single retort stills and double retort stills were all in use and each of these types were supplied by Shears of Bristol. Improvements would continue – attached is a single retort of Blairs, produced around the turn of the century with the open cooling head replaced by a modern condenser. Rectification heads would be added to retort stills in Barbados and Guyana but notably not Jamaica. You can find a rectification head on the Port Mourant double still in Guyana.

While there is little evolution in the simple batch (pot) stills of Scotland, Ireland or Cognac on the scale of that in the West Indies, there are some common improvements that have been adopted.

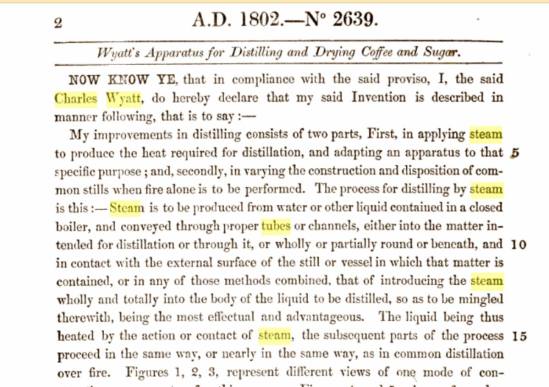

In 1802, Charles Wyatt patented the application of steam “tubes” to distillation instead of direct fired stills which avoids the burning the wash on the bottom of the still. Today almost all stills in Scotland are steam heated but even here the West Indians were the more progressive. The steam used in the Coffey stills was thought to destroy the esters and it would not be until 1887 before Glenfiddich installed a still with steam coils. Famed Jamaican chemist HH Cousins carried out research in Jamaica on the use of steam and found it superior. This resulted in a quicker widespread adoption in Jamaica of the steam coil over Scotland. The Americans would also be quicker to adopt steam distillation over direct fire. Famously today cognac must be distilled by direct fire.

“I am convinced from the results obtained at Shrewsbury estate in Westmoreland, that all home trade rums could with advantage be distilled in stills heated by a steam coil. Burnt rum should then be unknown. The fetish of the ‘direct fire’ that still lingers in the minds of Scotch whiskey distillers has no basis at all where Jamaica rum is concerned, since any excessive firing results in a most serious injury to the spirit produced”

H H Cousins, West Indian Bulletin, 1907

The earliest stills cooled the vapour by passing it through a simple worm (or coil). Originally this was solely atmospheric cooling but in 1771, German Chemist Wiegel invented the worm tub where the worm is placed in a tub into which cold water is continuously pumped. In 1825, William Grimble invented the shell and tube condenser which replaced the worm tub for cooling the distilled vapour. Barnard’s encyclopedic work on Scottish distilleries in 1887 shows they were widely in use by then. Today just a small minority of Scottish distillers use a worm tub and most rum producers in Anglophone Caribbean use shell and tube condensers. The shell and tube condenser proved superior because it cools the vapour markedly more slowly and this in turn has a significant impact on the copper’s catalytic effect in removing undesirable sulphur compounds from the spirit. As vigorous molasses fermentations tend to produce more sulphury components over other washes, the popularity and rapid adoption of the shell and tube condenser in rum is of little surprise.

Visiting the region you can see the culmination of this history with double retort stills (some with rectification heads) dominating the rum producers of the Anglophone Caribbean.

Part Three – Foursquare

The myriad of still designs from past is overwhelming. Nostalgia makes us believe there is something better that has been lost to time whereas the reality is that much of what was discarded was inferior to how we distill today. Innovations that did not deliver did not last. Evolutions that worked became the norm. Different spirit cultures evolved though the different routes that worked for them and the progressive rum distillation techniques may not have delivered for Scotch what they delivered for Rum.

By examining this brief overview of the evolution of distillation, everyone can better grasp what we do at Foursquare and why.

Our twin column continuous still is based on that design principle of separation of the analyser and the rectifier first developed by Coffey in the 1830s. Likewise it produces a spirit that complements rather than competes with the spirit produced by our batch still. However, unlike the classic Coffey still the still operates under vacuum pressure. Instead of our wash boiling at a little over 100°C, our wash boils at just about 80°C with the consequent marked improvement in spirit quality. The high suspended solid content of a molasses wash make this technological advance all the more rewarding.

Our two batch stills are the classic pot/double retort design as used throughout the West Indies from Grenada to Jamaica. A design developed in the first half of the 19th century, “unsurpassed” in the words of Wray. Our retorts feature cooling heads, a feature first developed by Pistorius (1817) and Corty(1818) and popular in the West Indies in the stills built by Shears. It was Simon Dore, great grandson of John Dore who suggested to us that we revive the use of cooling heads on retorts.

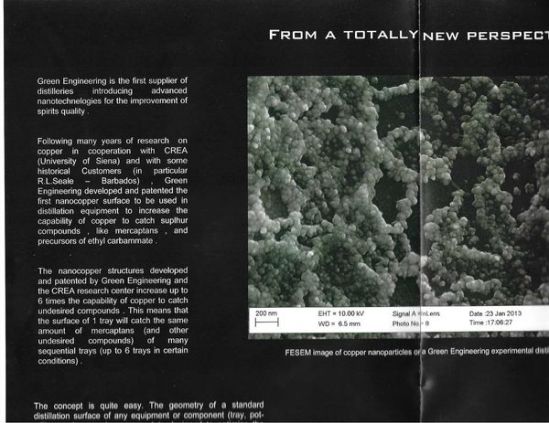

Apprenticed to John Dore were the Carter brothers who developed the Carter-Head, an evolution of the rectification heads found on Shear’s double still and Saint Marc Still of 1824. Loch Lomond operates similar rectification heads today. At Foursquare, we have our own evolution of the Carter-Head on both of our stills. We have incorporated in these heads the use of ‘nano copper’ surfaces. This was developed by the CREA Research Centre (University of Siena) in collaboration with Green Engineering. The practical effect of these copper surfaces is to improve the catalytic effect of the copper. In this way, the thermodynamic process is unchanged but the chemical effect is improved. That is to say, one nano copper tray has the catalytic effect of six trays but the rectification power of a single tray.

Our older batch still has steam coils but our new batch still features a twin system of steam coil and bain-marie. A bain-marie is a steam or water jacketed still developed in the 16th century but mainly used by alchemists. Today, several craft distillers use small stills heated via a bain-marie. The twin system provides the most consistent and even way of heating a batch still. A smoky flavour is a natural component of a peated whisky but a smoky flavour in rum is just bad distillation.

We also use the shell and tube condenser on our batch stills for its superiority over the older worm tube vapour cooling system. Sulphury, metallic, “petrolly” rums are not our style.

As a homage to all that that has been learned and incorporated from the past, the man door on our new batch (pot) still is from an actual cast as used by John Dore & Co Ltd.

There is another innovation on our latest batch still, probably the most ambitious of all. But we will wait till its proved in the field before revealing.

Big thanks to Richard for agreeing to allow me to collate this information….Stay tuned for the Six Part collected article “Yeast In Rum (or S. Pombe Revisited)”

© Steven James, Rum Diaries Blog and Richard Seale. Unauthorized use and/or duplication of this material, both written and photographic without the express and written permission from this blog/sites author and owner is strictly prohibited. Excerpts and links may be used, provided that full and clear credit is given to Steven James, Richard Seale and Rum Diaries Blog with appropriate and specific direction to the original content.

Lucky we are in lockdown plenty of time for reading. Nice piece boss 👍